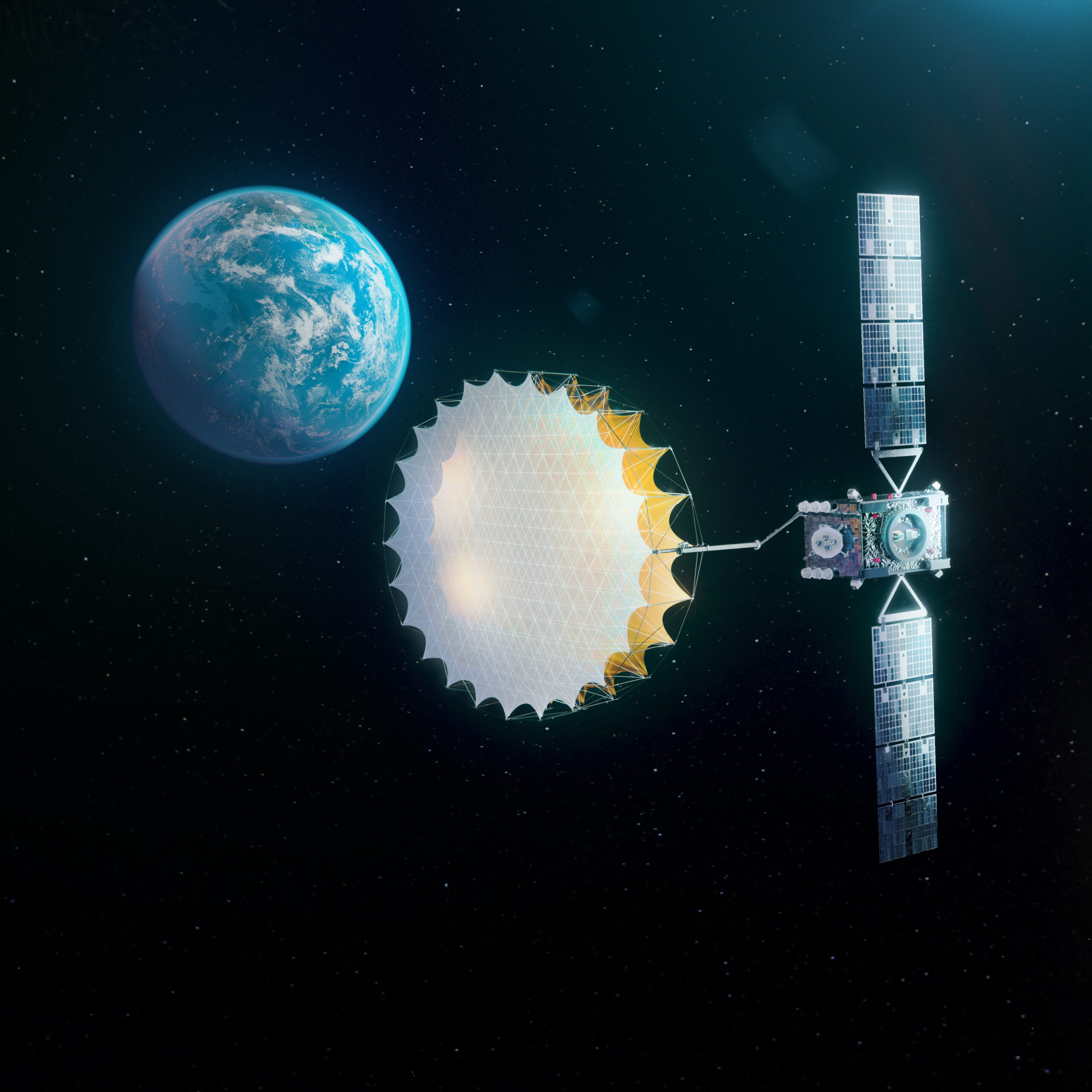

Powering next-generation

Satellite Communications

In Space, and anywhere on Earth

Small satellites, Big reach

We’re expanding the horizons of Satellite Communications.

HummingSat is the first commercial Geostationary small satellite, opening up new frontiers in Satcoms to better connect and protect the world.

Connecting and protecting every corner of the world

Hello

HummingSat

®

Geostationary

Reach

Geostationary

Reach

New Opportunities

in Satcom

New Opportunities

in Satcom

Small Sat,

Big Performance

Small Sat,

Big Performance

Components and Sub-Systems

SWISSto12 is a leading provider of Radio Frequency products and sub-systems – all leveraging our proprietary 3D printing IP.

With over 1,000 products already in orbit and over 100 sub-systems deployed on aircraft and ships, our partners depend on our robust, high performance products for the most critical applications.

The journey

Named in ViaSatellite's "Top 10 Hottest Companies" and a World Economic Forum Technology Pioneer, SWISSto12 is the first growth stage company to sell geostationary satellites to global satellite operators.

Our team

Our team of engineers, innovators, and commercial experts is based in Switzerland, California, Washington DC, Denmark and Spain.

Join us

We’re growing fast to build ambitious products. Explore opportunities - from engineering to testing, from quality control to business development and admin.

Shaping the

Future of Satcoms

Pioneering a new era of

Radio Frequency communications

3D Printing

SWISSto12 holds the largest IP portfolio for Space RF products based on 3D printing (or additive manufacturing). Our technology enables the design and manufacture of complex, highly performing, lightweight antennas, as well as RF filters and waveguides.

Manufacturing

SWISSto12’s patented manufacturing process offers state-of-the-art RF, mechanical and thermal performance as well as unprecedented design flexibility.

Heritage

Trusted by aerospace leaders, we have over 1,000 3D-printed RF products in orbit with proven performance over the spectrum from L to Q-V band.